The A510 Heavy Duty AC Drive is an easily configured versatile drive product that will control all general applications such as fans, pumps, conveyors, and mixers. It comes standard with a simple to select preset application parameters for many commonly used applications.

Despite its simple and easy approach, the A510 is loaded with features to solve tough and demanding applications such as reciprocating pumps, compressors and high torque/ high inertia loads

Advanced algorithms allow the A510 to perform tight and precise speed control when coupled with encoder feedback on the motor being controlled.

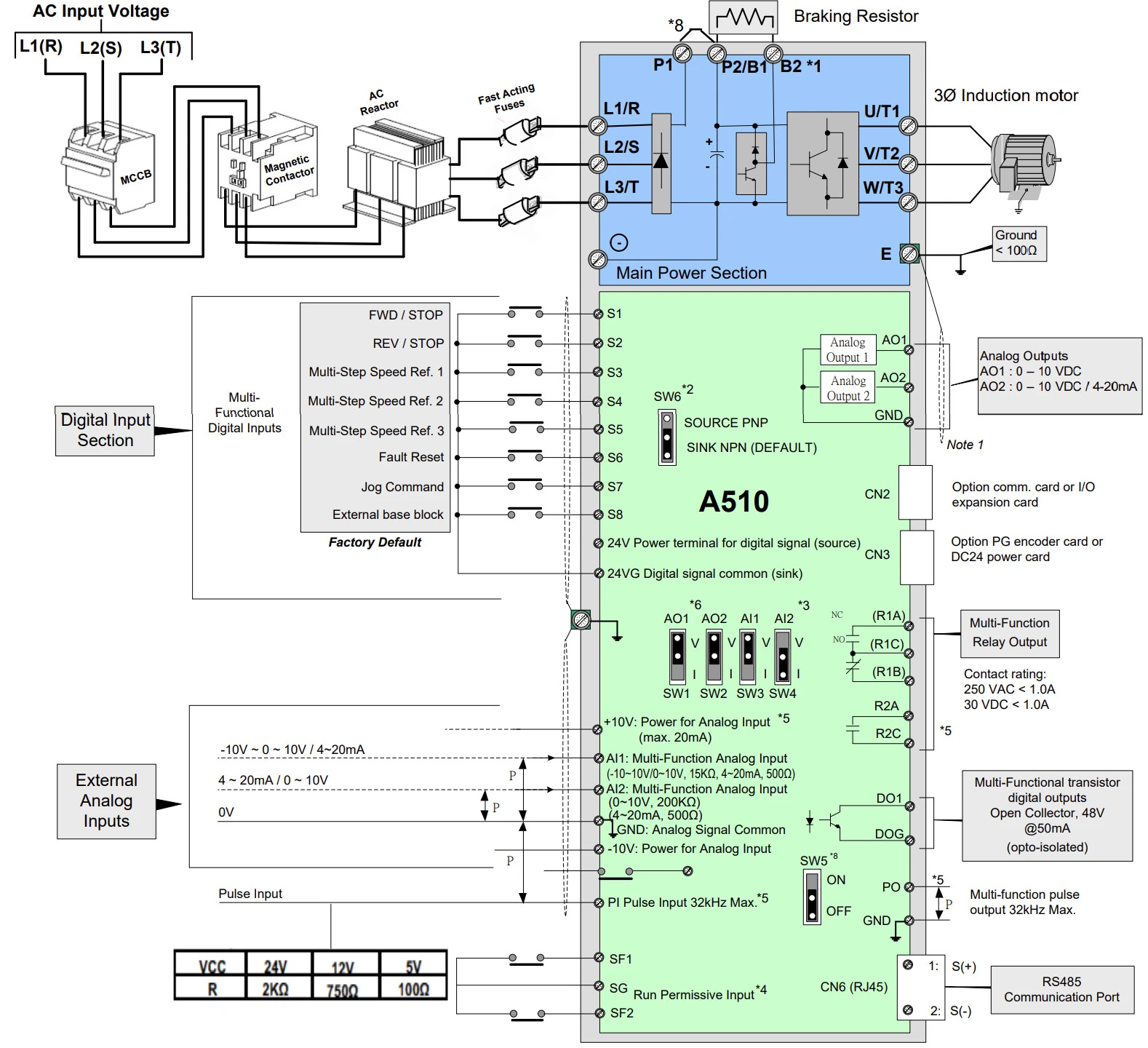

Notes:

1: Models 230V 1 to 25HP and 460V 1 to 30HP or lower ratings have a built-in braking transistor. To use this braking transistor a braking resistor can be connected between B1 and B2.

2: Use SW6 to select between Sink (NPN, with 24VG common) or Source (PNP, with +24V common) for multi-function digital input terminals S1 to S8.

3: Use SW3/SW4 to switch between voltage (0 to 10V) and current (4 to 20mA) input for Multi-function analog input 2 (AI2). Besides please also check parameter 04-00 for proper setting.

4: Run Permissive input SF1 and SF2 is a normally closed input. This input should be closed to enable the inverter output. To activate this input remove the jumper wire between SF1/ SF2 and SG.

5: When using the open collector for pulse input, it doesn’t need resistance because of built-in pull-up resistance.

6: AO1/AO2 default setting is 0~+10V.

7: Both 230V class 50HP to 150HP and 460V class 100HP to 425HP have built-in DC reactors.

8: It need turn on the switch for the terminal resistor RS485 in the last inverter when many inverters in parallel connection.